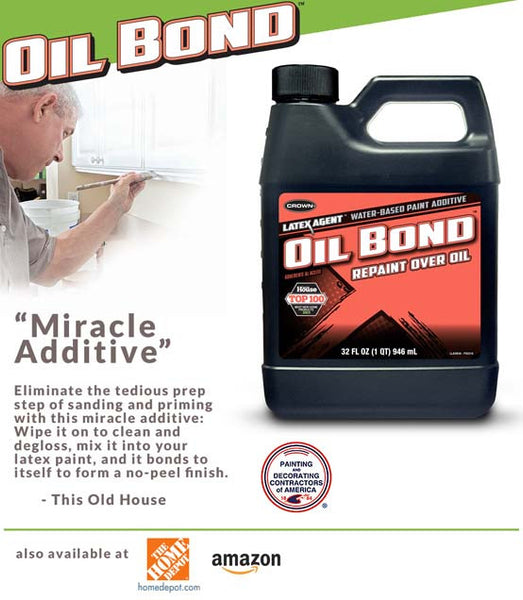

Oil Bond - Paint Additive - 1 Quart

Shares :

Click here to learn how to paint your kitchen cabinets without sanding!

• Great for use on cabinets, trim, furniture and doors.

For expedited shipping call 832-300-4089.

- Oil Bond is a truly unique water based, low VOC product. Oil Bond is designed and formulated to work in all latex paint. Oil Bond is first wiped on oil or water based paint, varnish, lacquer, polyurethane or even powder coated items with a clean, lint free rag. The wiped on Oil Bond contains cleaning surfactants, deglossing agents and priming, one part, self-crosslinking resins. The product will then clean, degloss and pre-prime painted surfaces, most clear coat surfaces (not laminates or plastics) and most powder coated surfaces (not automotive, clear coat finishes). Allow the wiped on Oil Bond to dry for an hour to overnight. After that add 16 ounces per gallon of Latex paint and the Oil Bond will cross link to the pre-primed product left behind in the wiping step. The additive is only needed in the base coat if more than one will be applied. Oil Bond can stop minor bleed through, but if the rag used for wiping the surface comes out colored from bleeding from stains or pigment transfer, then a blocking primer may be necessary.

- SHAKE WELL FOR AT LEAST 30 SECONDS

- PRETREAT - Pretreating the surface with the Oil Bond latex paint additive will effectively clean, degloss and assist adhesion of the latex paint to the project surface:

- Apply the Oil Bond product to a clean, lint free cotton rag and wipe the surface with a moderate amount of product. Regularly reapply the product onto fresh, clean areas of the rag during the process to assure that the surface is properly prepared and change rags as dirt is absorbed onto the rag. Appropriate gloves are recommended. Any further cleaning of the surface before or after application is not necessary.

- After pretreating, allow the surface to dry for one hour.

- ADD TO LATEX PAINT:

- Begin by adding 16 oz. of the Oil Bond latex paint additive to one gallon of latex paint. Stir well.

- Apply the latex paint with Oil Bond additive to project surface using brush, roller or spray in the first coat of paint. Additional coats do not require the Oil Bond additive.

- Allow to dry as directed by the latex paint instructions. Full cure of the paint may take a day or two, depending on the conditions (temperature, humidity, etc.) The coating will be the toughest after 2-3 days and should completely harden within about one week.

NOTE: If the color from project surface begins to transfer onto the rag or the finish begins to loosen from the surface during pretreatment, then pretreating with a scouring pad is necessary (using a multipurpose primer may be used to avoid bleeding). If a smooth surface is not achieved after pretreating, the surface will need to be sanded and primed.

NOTE: For use in spray equipment - Add the Latex paint with Oil Bond additive as directed and dilute as necessary with extra water to meet the viscosity requirement for your spray equipment per the manufacturer’s directions.

It is the user’s responsibility to determine whether this product suits the purpose of the user’s application.

-->Click here to learn how to paint your kitchen cabinets without sanding!

• Great for use on cabinets, trim, furniture and doors.

For expedited shipping call 832-300-4089.

- Oil Bond is a truly unique water based, low VOC product. Oil Bond is designed and formulated to work in all latex paint. Oil Bond is first wiped on oil or water based paint, varnish, lacquer, polyurethane or even powder coated items with a clean, lint free rag. The wiped on Oil Bond contains cleaning surfactants, deglossing agents and priming, one part, self-crosslinking resins. The product will then clean, degloss and pre-prime painted surfaces, most clear coat surfaces (not laminates or plastics) and most powder coated surfaces (not automotive, clear coat finishes). Allow the wiped on Oil Bond to dry for an hour to overnight. After that add 16 ounces per gallon of Latex paint and the Oil Bond will cross link to the pre-primed product left behind in the wiping step. The additive is only needed in the base coat if more than one will be applied. Oil Bond can stop minor bleed through, but if the rag used for wiping the surface comes out colored from bleeding from stains or pigment transfer, then a blocking primer may be necessary.

- SHAKE WELL FOR AT LEAST 30 SECONDS

- PRETREAT - Pretreating the surface with the Oil Bond latex paint additive will effectively clean, degloss and assist adhesion of the latex paint to the project surface:

- Apply the Oil Bond product to a clean, lint free cotton rag and wipe the surface with a moderate amount of product. Regularly reapply the product onto fresh, clean areas of the rag during the process to assure that the surface is properly prepared and change rags as dirt is absorbed onto the rag. Appropriate gloves are recommended. Any further cleaning of the surface before or after application is not necessary.

- After pretreating, allow the surface to dry for one hour.

- ADD TO LATEX PAINT:

- Begin by adding 16 oz. of the Oil Bond latex paint additive to one gallon of latex paint. Stir well.

- Apply the latex paint with Oil Bond additive to project surface using brush, roller or spray in the first coat of paint. Additional coats do not require the Oil Bond additive.

- Allow to dry as directed by the latex paint instructions. Full cure of the paint may take a day or two, depending on the conditions (temperature, humidity, etc.) The coating will be the toughest after 2-3 days and should completely harden within about one week.

NOTE: If the color from project surface begins to transfer onto the rag or the finish begins to loosen from the surface during pretreatment, then pretreating with a scouring pad is necessary (using a multipurpose primer may be used to avoid bleeding). If a smooth surface is not achieved after pretreating, the surface will need to be sanded and primed.

NOTE: For use in spray equipment - Add the Latex paint with Oil Bond additive as directed and dilute as necessary with extra water to meet the viscosity requirement for your spray equipment per the manufacturer’s directions.

It is the user’s responsibility to determine whether this product suits the purpose of the user’s application.